RELATED Robotics & End of Line PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

Bundle it, pack it, seal it, palletize it, wrap it, and go: ProMach offers customers a single source for all their robotic and end of line packaging needs, from standalone applications to complex packaging systems. We also provide fully integrated end of line systems that offer the shortest path to production, as well as complete project management capabilities including financial and system-performance responsibility. With entry-level to high-speed applications for nearly all industries and markets, ProMach helps all types of customers achieve better performance and create greater value.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

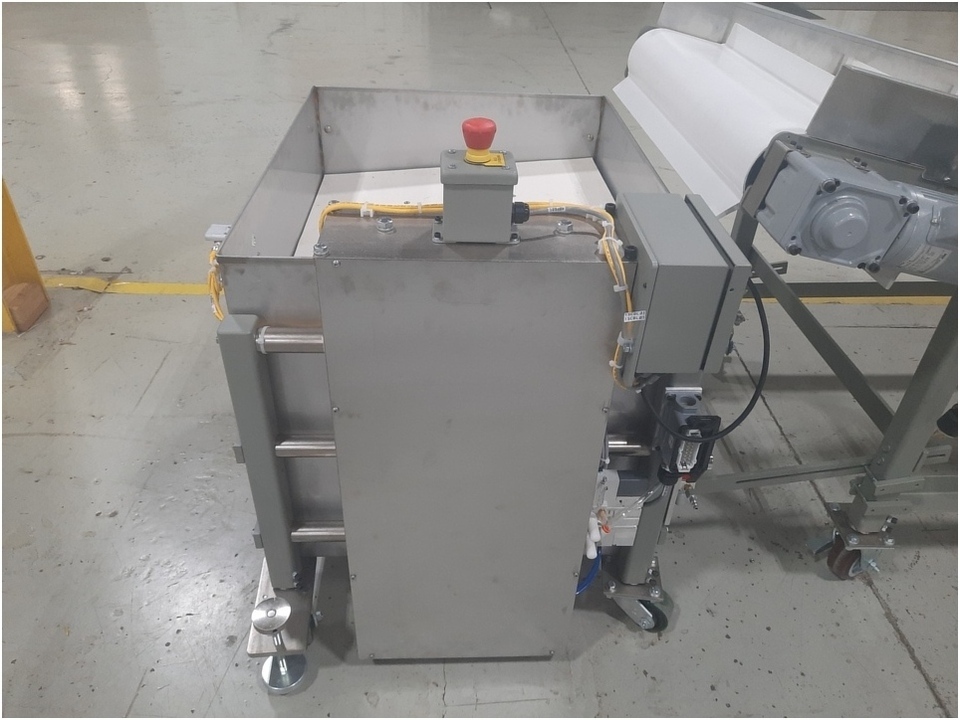

learn moreRennco's NextGen Baggers are ideal for multiple industries including: